History of Our Products

Machinery

for Overseas

1970’s

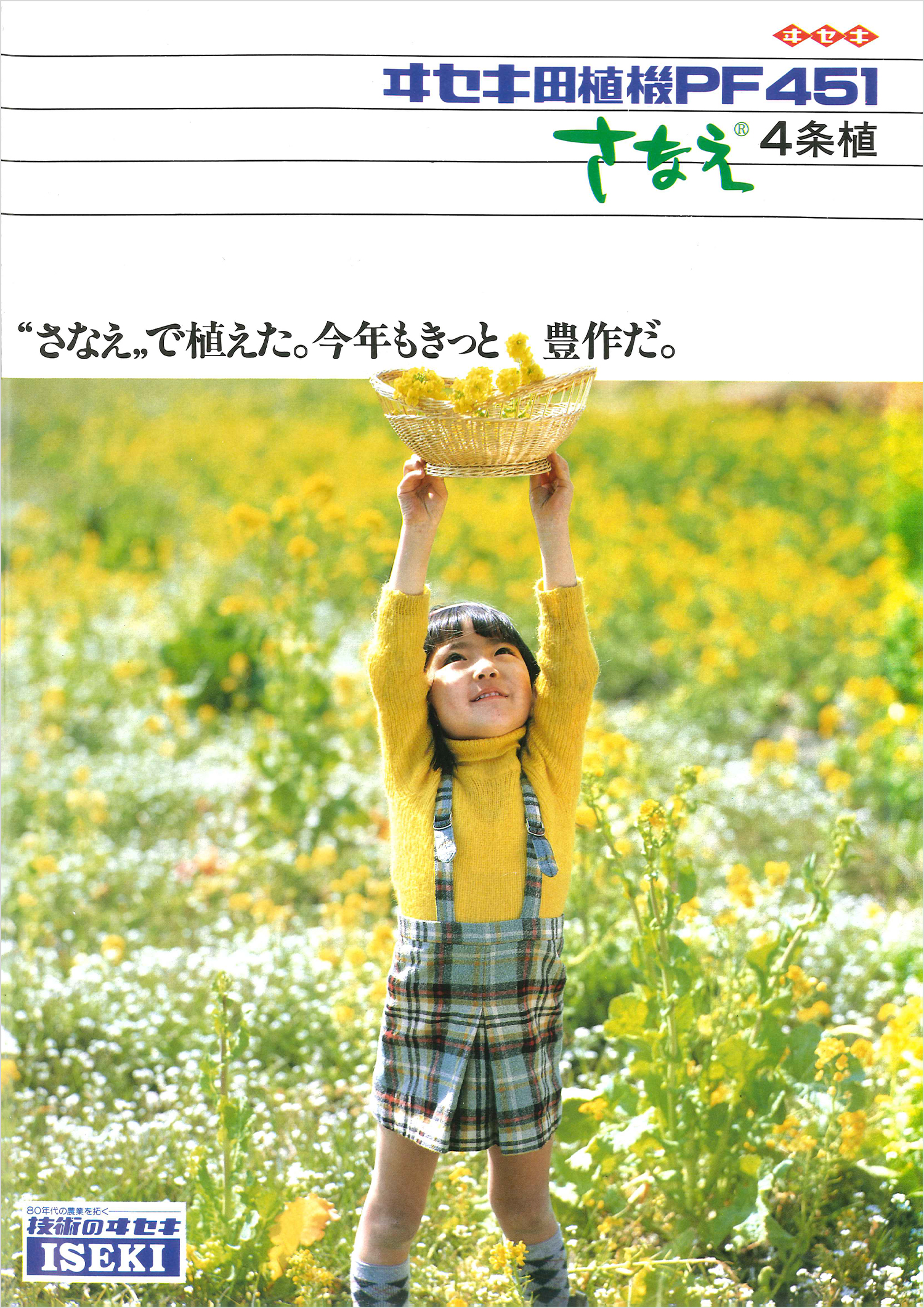

PF series

First exported walk-behind rice transplanters

for overseas

Sales area: South Korea, Taiwan, China

Lightweight, highly operable and convenient, and possessing outstanding planting precision, this was our first walk-behind rice transplanter to be exported. In the 1970’s, while plowingoperations were gradually becoming more mechanized in various regions, transplanting tasks were for the most part reliant on human labor. Given this situation, we exported this walk-behind rice transplanter, equipped with Sanae-matic that has the sensitivity to stand up well to irregularities in plowing surfaces, and Sanae-finger for highly stable and efficient planting performance contributed to free farmers from exhausting labor.

1974

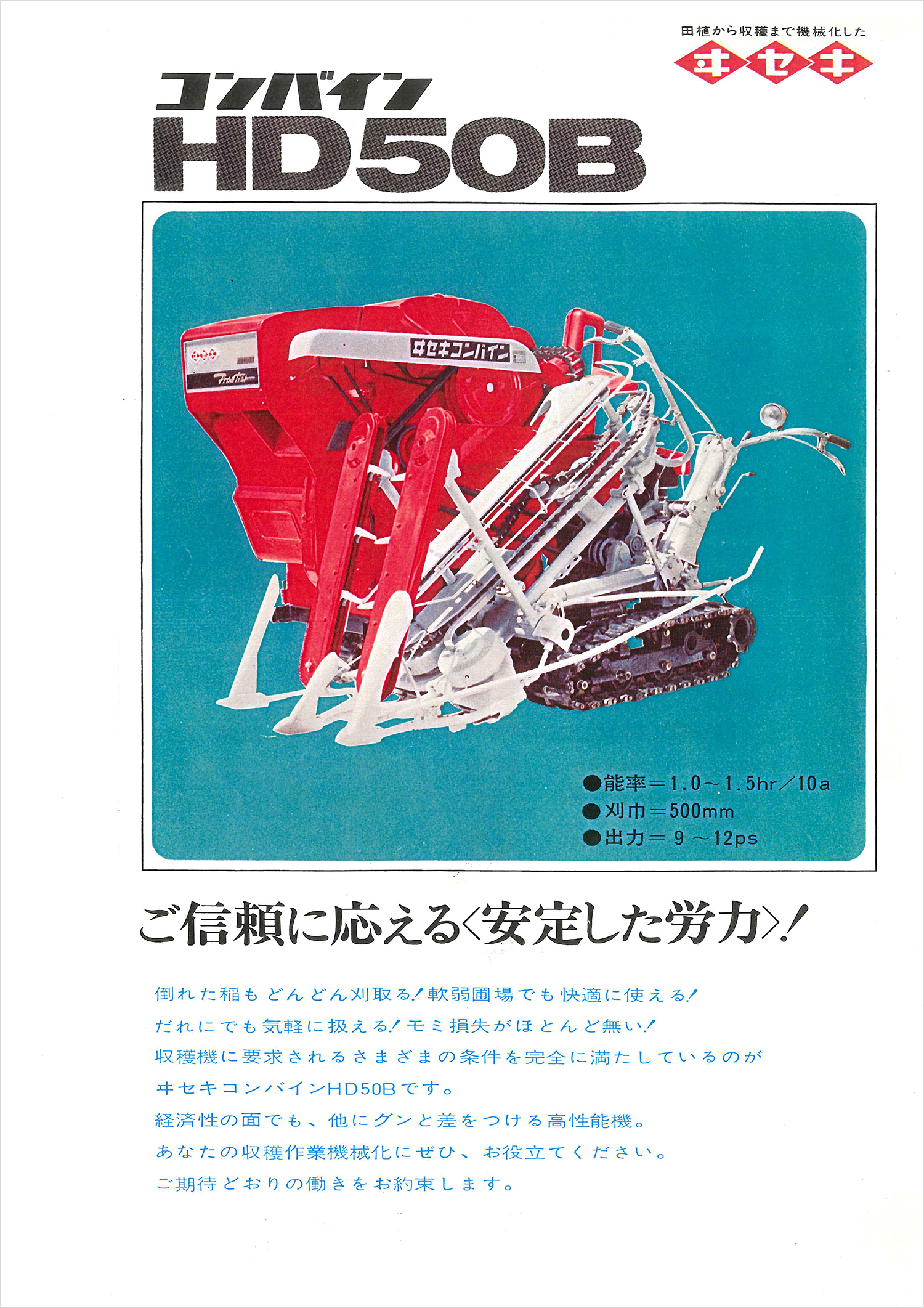

HD50

First exported combine harvesters for overseas

Sales area: Asia

We took initial steps to bring to overseas markets its world-first head-feeding combine harvester, which integrates a threshing machine and a harvesting unit on a traveling chassis to be adapted to rice paddy in Japan. The overseas introduction of the combine harvester, which notably shortened work time from harvesting to threshing compared to conventional models, contributed to a substantial reduction in the workload of local farm workers.

1976

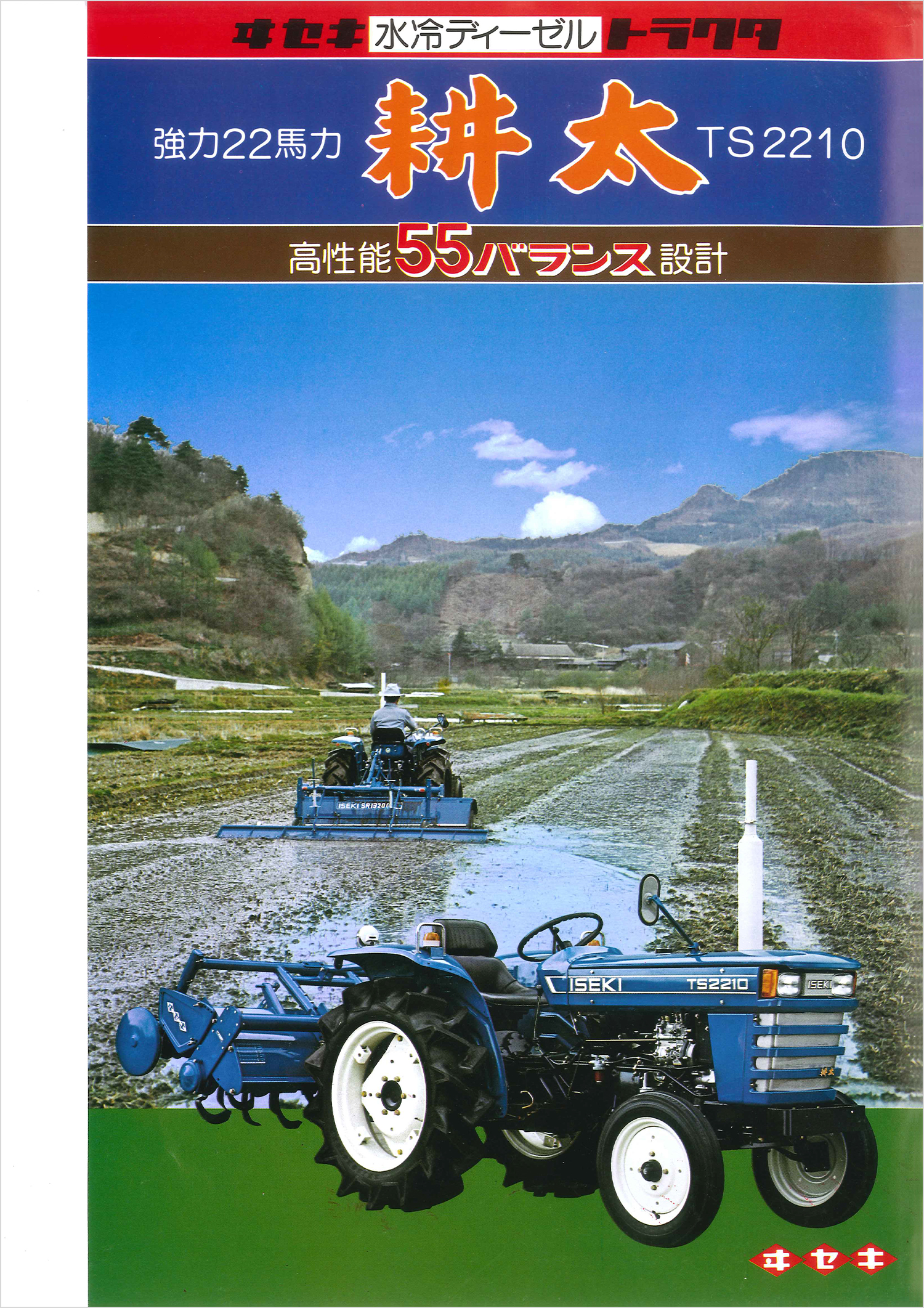

TS2210

First exported tractors to Korea

Sales area: South Korea

The TS series were the first tractors we exported to South Korea. ISEKI’s unique “55 balance” (weight distribution between front and rear wheels) maintains the ideal balance of the machine under any conditions, enabling this high-performance tractor to engage in a full lineup of operations with stability, including towing, driving, traveling, turning, and climbing a slope. This tractor, which offers stable drivability, robust maneuverability, a comfortable ride, as well as extreme versatility, performed with much acclaim in South Korea, and naturally was also popular in Japan.

1976

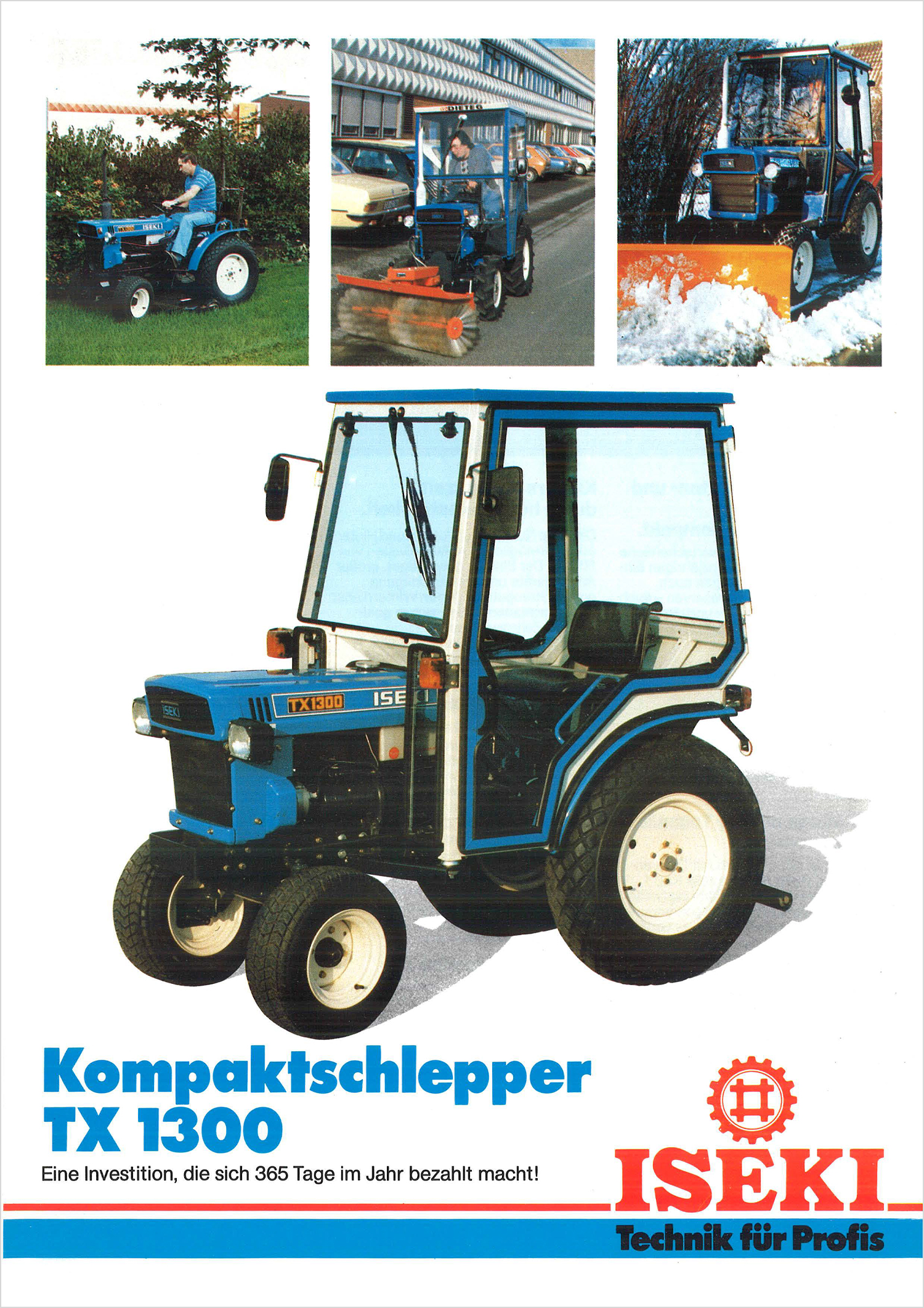

TX1300

Started shipment of tractors to Europe

Sales area: Europe (Shipped to the United States, Hawaii, and Indonesia in the same year)

This was the first-generation model we developed for its tractor business in Europe since 1976. As a small but high-quality tractor with a full-fledged transmission structure and air-cooled engine, we promoted it for agricultural use targeted to small-scale farms as we did in Japan. While at the same time, in Europe, it was found to be suitable for the landscape maintenance market, such as for cleaning parks and streets, and pushed forward on pioneering this new market.

1980

HL1500

First exported tractors to Taiwan

Sales area: Taiwan

This combine harvester exported to Taiwan automated the three basic elements of combine operation: row alignment, cutting height adjustment, and checks of threshing depth. Furthermore, adopting the automatic checking mechanism for feeding depth (A.C.F. sensor) has helped threshing depth adjustment, which is difficult for unexperienced-farmers . Thanks to a high-performance harvesting mechanism, comfortable operation, and durability and reliability, this combine harvester has been used to great effect in Taiwan.

1984

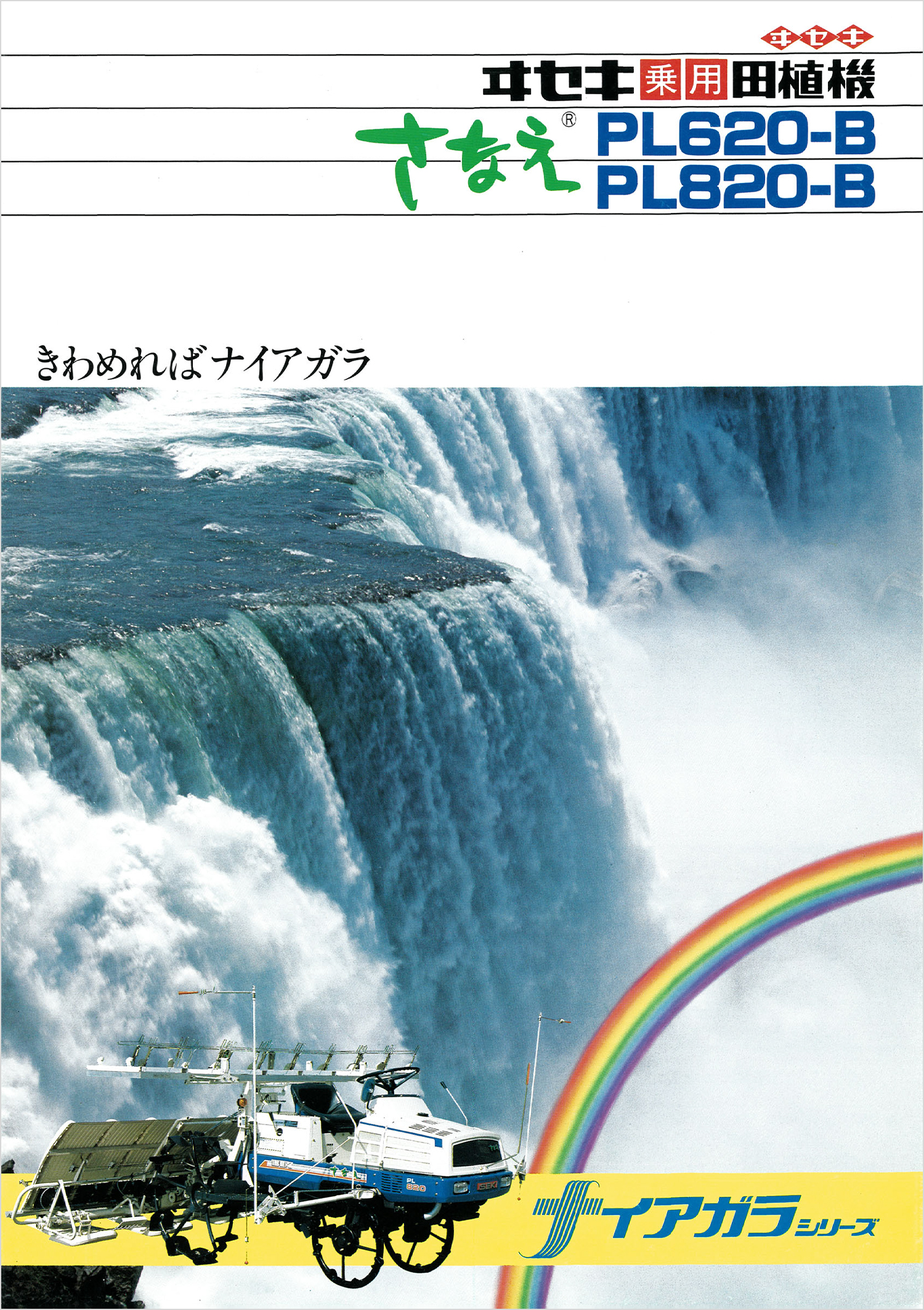

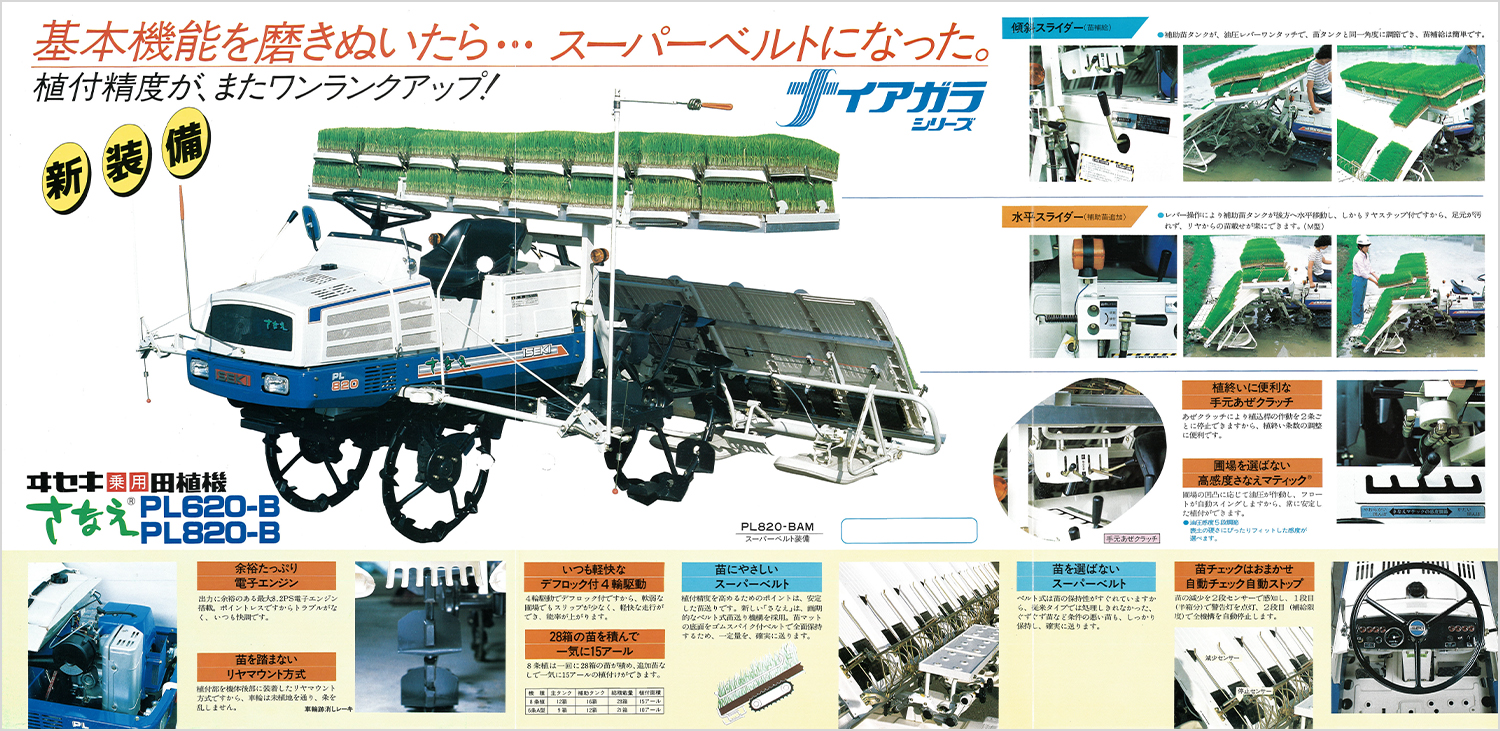

PL820

First exported ride-on rice transplanters

for overseas

Sales area: Taiwan

Responding to the demand in Taiwan, to switch over walk-behind type to ride-on type transplanters, this is the first exported ride-on rice transplanter for overseas equipped with the highly sensitive Sanae-matic that can accommodate a variety of fields. Hydraulic pressure is activated according to a field’s unevenness, and the float swings automatically to enable consistently stable planting. In addition, the adoption of an innovative, seedling-friendly belt-type feed mechanism realized improved planting accuracy. Equipped with these capabilities, the ride-on rice transplanter contributed to improved efficiency in rice transplanting operations in Taiwan.

1987

TL2700

First exported tractors to Taiwan

Sales area: Taiwan

This first tractor we exported to Taiwan equipped with Radar-matic, which swiftly responds to changes in various field conditions, such as slopes and surface irregularities, and achieved high operational efficiency by maintaining a preferable operational balance —it remains stable even when it is raised or lowered, and keeps horizontality even when it is tilted. Being equipped with ISEKI’s unique safety mechanism that automatically stops rotation when the rotary is raised, then once again rotates when lowered prevents mud splatter when turning or reversing, allowing for safety operation. These features have been appreciated not only in Japan, but in Taiwan as well.

1988

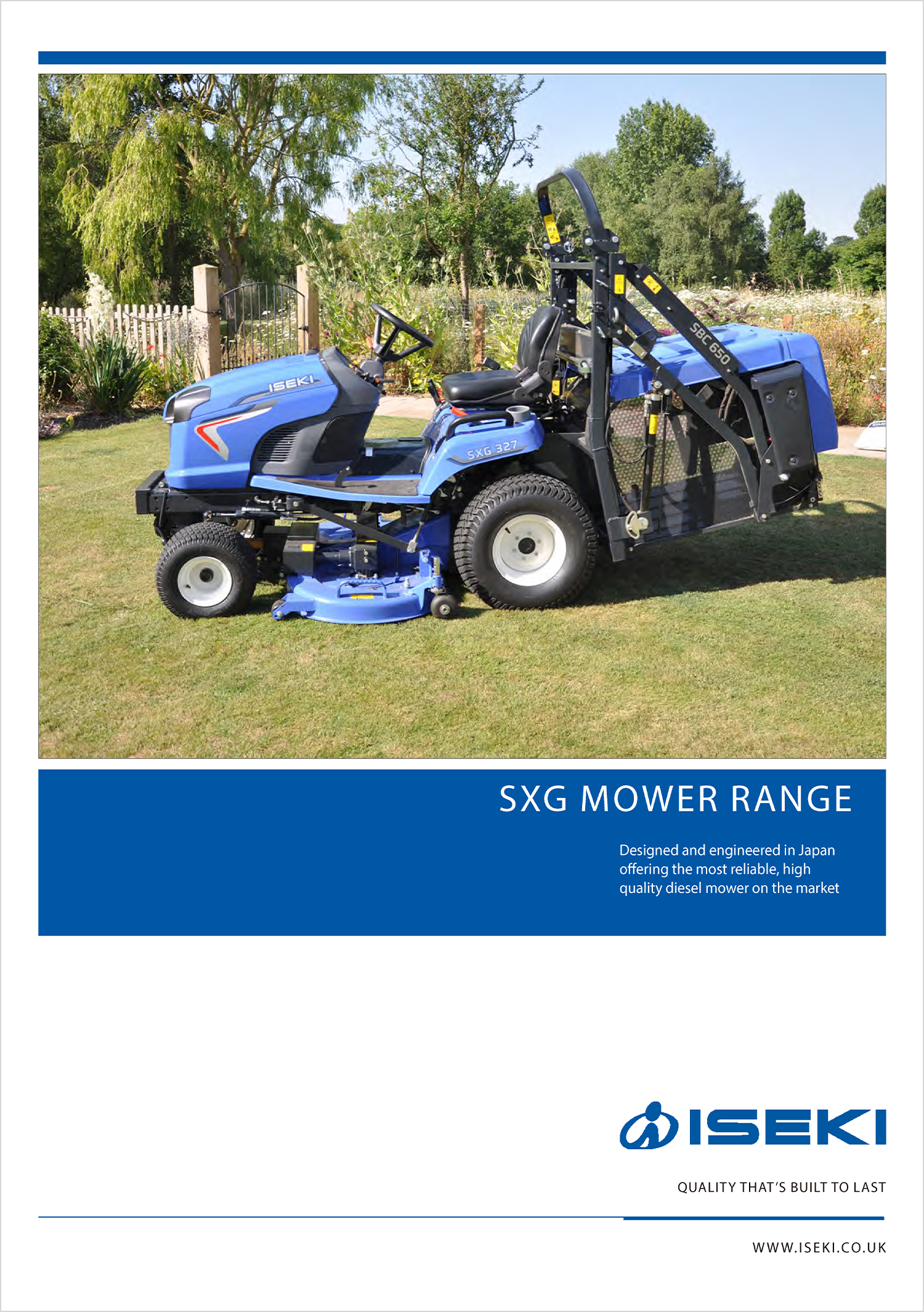

SG13/15/17

First shipment of riding mowers to Europe

Sales area: Europe, Oceania

We first introduced a mid-mount-type ride-on lawn mower to the European market in 1988.

As a high-performance machine equipped with a diesel engine, sales expanded to professional landscapers. The introduction of the SG series marked a major step forward in establishing us as a leader today in the market.

2002

MFGC2300

Sub-compact tractors for North America

Sales area: North America

In 2002, ISEKI developed our first "subcompact tractor" for the North American market. Designed to meet the growing demand from hobby farmers and attract users from the riding garden market, the MFGC2300 was introduced as a tractor that combines the functionalities of garden equipment and tractor operations. Today, it has become one of core products for the North American market.

2004

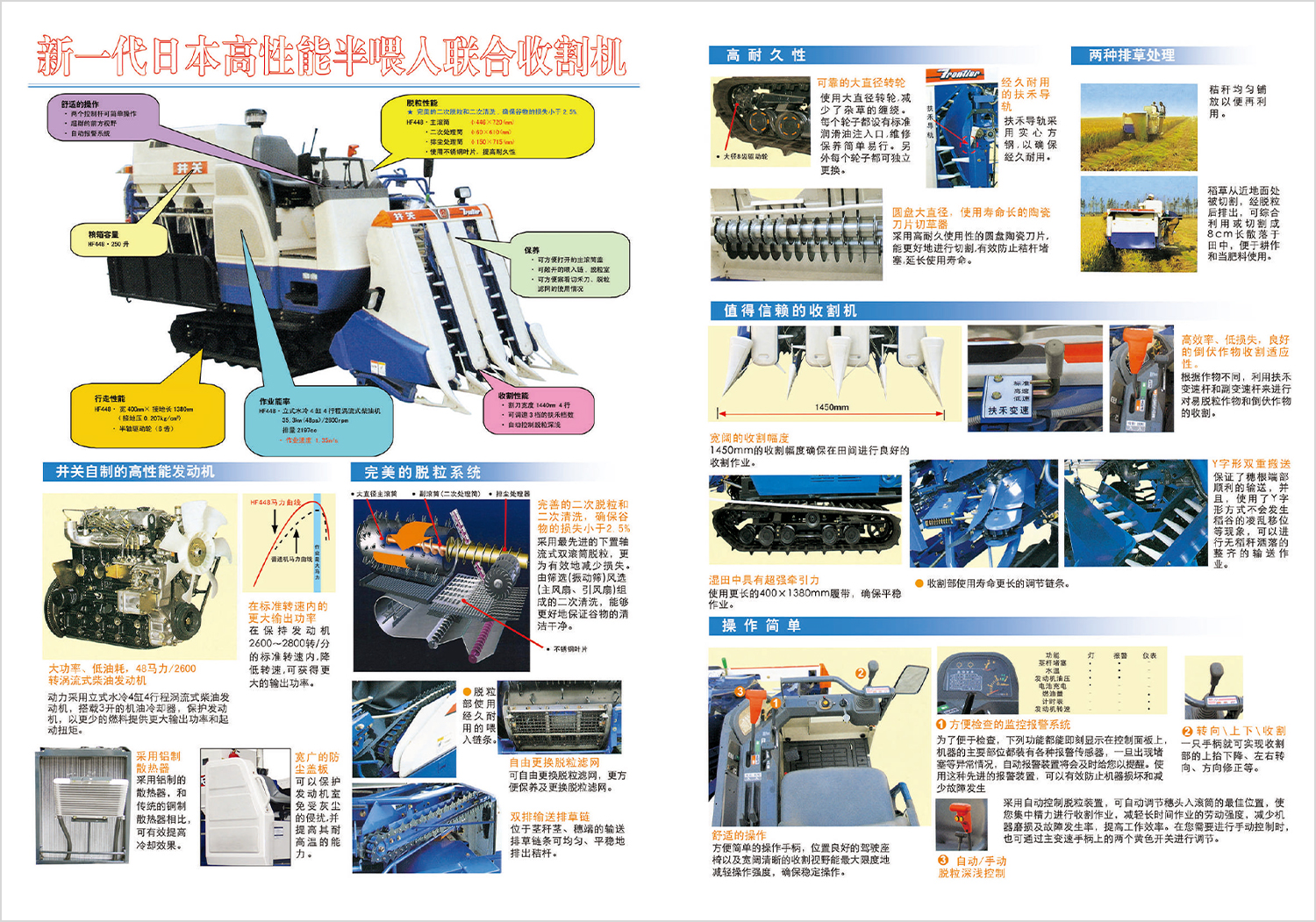

HF448

Head-feeding combine harvesters cross the ocean

We launched our first Head-feeding combine harvester specialized for Chinese market. Head-feeding combine harvesters emerged to meet the needs of rice paddy agriculture in Japan, but have now been introduced to overseas markets including China, Korea, Taiwan and others that have rice as a staple. This combine harvester was the first of its kind to be designed specifically for the Chinese market and has been produced at Iseki–Changzhou Mfg. Co., Ltd. in China since 2004.

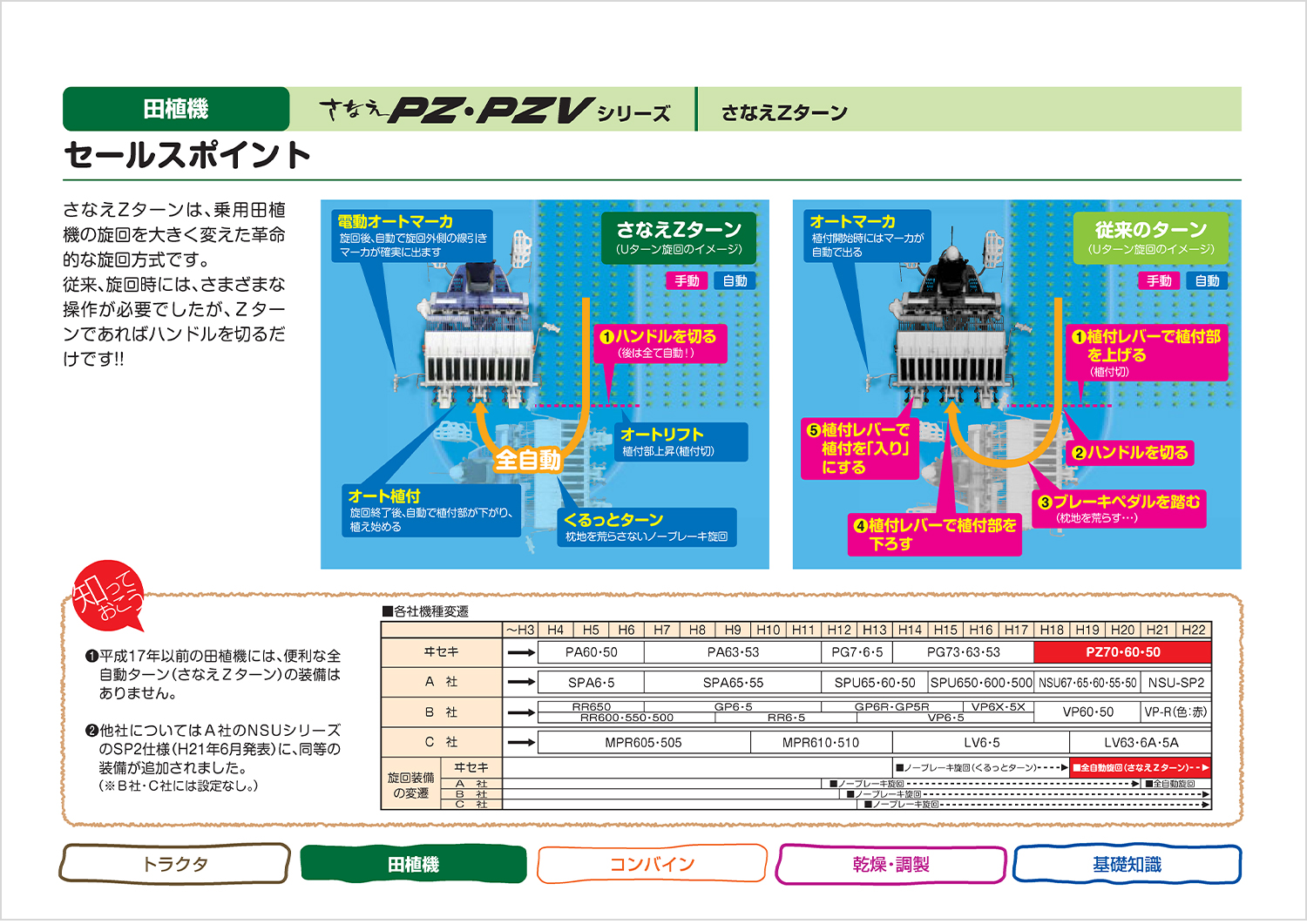

2012

Sales area: China

This was a diesel engine-powered ride-on rice transplanter for China. At the time, as gasoline engines were the mainstream for ride-on rice transplanters in China, mechanization of rice planting work was a challenge in the northeast inland of the country where fuel distribution networks were not well established. Then, in 2012, we developed and sold ride-on rice transplanters with diesel type , as even in that region a stable supply had been achieved. This machine became a major product throughout China: excellent adaptability to field conditions owing to its high output and torque and the improved work efficiency of its “Z Turn,” which automates turning operation and the fertilizer.

2020

Sales area: Europe

For over 50 years in its European business, we have continued to develop products that reflect the feedback of customers, and this compact tractor with 30-40 horsepower is a product evolved to meet the needs of professional landscapers in maintenance work contracted from local municipalities. In the development of this product, we pursued high performance, quality, and equipment specifications, as well as a machine size appropriate to operation, usability, and comfort. This tractor has been appreciated in the landscaping field in Europe.

2020

Sales area: Europe

A riding lawn mower (large-sized front mower) in the SF series is a major product for the European market. In contrast to the side discharge system, which discharges mown grass from the side of the mowing deck located in front of the machine, for this model series we adopted a central collector system, which collects mown grass in a collector with a hose in the center of the machine. As the hose does not protrude from the side of the machine, a feature of the machine is that it is easy to turn in a small space and offers good usability to meet the needs of professional users.

2023

Sales area: Europe, Oceania

This is the latest series of riding lawn mowers that follow in the footsteps of the SG series. It uses a central collection system and has improved basic specifications and usability including a large-capacity grass collector that provides ample work and an improved maximum speed that shortens work time. This product is also compatible with HVO (Hydrotreated Vegetable Oil) fuel to reduce environmental impact by cutting CO2 emissions.